The Story of the Shrike

A very short version of a very long (and continuing) saga.

Genesis, 1965:

This is the “Short-Ribs Special”, an SCCA Class H-Modified sports-racing car a buddy and I built from a clapped-out old chassis and basket full of parts. It was a real hoot to drive, although hopelessly underpowered. In the intervening years I longed to recapture the feel of a low, light, open racing machine.

I sold that car to pay for a week at the Jim Russell International Racing Driver’s School at Willow Springs. On the last day of School I remember hearing Graham Hill win Indy in a Lotus-Ford. The School cars were Lotus 31s, 1,000 cc Ford powered Formula 3 cars. A pointer: never enter Turn 3 at Willow in a Lotus 31 on a trailing throttle…

Lotus 31 at Willow Springs:

1967:

Shelby-Wallis turbine-powered Indy car: my first automotive design job. My part was small and the company folded when the cars were finished.

1968-’80:

Serious chassis and suspension design experience with Lear Motors in Reno, and Dutcher Corporation in San Diego, trying to drag the steam powered automobile kicking and screaming into the 1970s. This is the California Clean Car, the first (and only) commercial product development ever funded by the California legislature. The front and rear suspension design is mine.

This car became part of the Harrah’s museum, then the National Auto Museum in Reno. As of 2008 it is owned by Jay Leno, on loan to the Petersen Museum in Los Angeles.

The ‘70s also brought racing experience in amateur Motocross, my daily drivers being a series of Yamaha Enduros highly modified for off-road racing.

The Turning Point:

Thanksgiving weekend, 1978: desert riding near Devil’s Playground, my riding buddy of many years collided with a dune-buggy at high speed, eventually losing his leg and nearly his life. It took us 6 hours to get him to a hospital. Bad deal. It took a good bit of the fun out of motorcycling.

As the months passed, I turned my time and talent

toward designing a vehicle that would preserve some of the feel of both

motorcycling and sports car racing, something very different. The idea for the Shrike was born.

1979: INITIAL CONCEPT, 1F/2R, HONDA CIVIC DRIVETRAIN, MONOCOQUE CHASSIS/BODY

My research into the dynamics of 3-wheeled vehicles made it clear early on that the 1F/2R (one front wheel / two rear wheel) arrangement had very serious drawbacks for a high-performance machine. While I an intrigued by the idea of a monocoque structure, I am concerned about intrusion into the driver’s space in a collision. So, I rather reluctantly turned my attention to the 2F/1R (two front, one rear) concept, with a tube frame.

The first parts actually purchased were a plastic bucket seat, aftermarket steering wheel, and the rack and pinion steering gear from a 911 Porsche. I can recall clearly that night, I sat in the seat, reclined to a comfortable angle and held the steering wheel at arms length. As I sat there I could visualize the car taking shape around me. It could work. I started taking measurements.

My design priorities were (and remain) as follows:

DESIGN PRIORITIES:

Individuality: 5.

Lateral Acceleration: 5

Crash Safety: 5.

Accident Avoidance: 4.

Cost to Produce: 4.

Ease of Manufacture: 4.

Simplicity: 4.

Longitudinal Acceleration: 3.

Operating Economy: 2.

Convenience: 1.

Appearance: 1.

Passenger(s) Accommodation: 1.

With these values guiding my thinking, I began dreaming, designing, visualizing, sketching, drawing, and worked up the first scale model of the chassis/body concept using soda straws and manila folder paper. I added a bit of paint, fashioned some wheels from foam plastic, hired G.I. Joe as my development driver and this is what rolled out:

1981: First model, paper and

straws. Note the use of G.I. Joe

as driver:

This could work!

1982: Then a wooden model, 1/8

scale:

Yes, this is the scale model. The engine and rear suspension are from a 1/8 scale plastic model of the Suzuki 6-cylinder road bike.

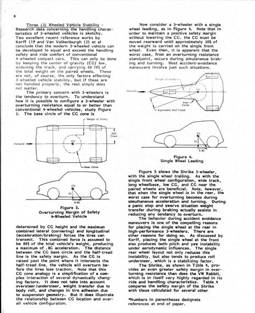

1983: SAE Technical Paper 831182 written and presented at the West Coast Meeting in Vancouver, BC. Excerpts below:

The layout was based on a Honda CX-500 V-Twin:

The CX-500 was chosen for its shaft drive, liquid cooling, and fairly small size. When it came time to locate one, I opted for slightly more power, finding an inexpensive Yamaha Maxim 650.

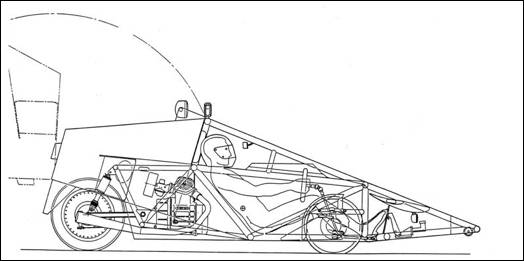

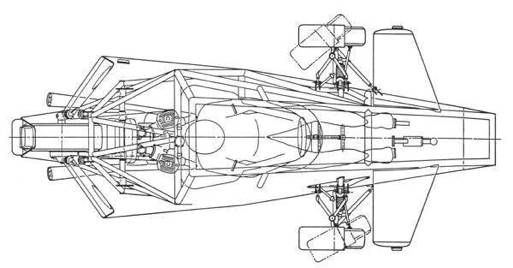

1983: CHASSIS LAYOUT USING YAMAHA 650 MAXIM

1 + 1 seating arrangement allows for small passengers, short rides.

650 MAXIM LAYOUT:

FRONT

SUSPENSION LAYOUT

Uses uprights, spindles, rotors, calipers, springs and dampers from 1967 Triumph Spitfire Mk. II

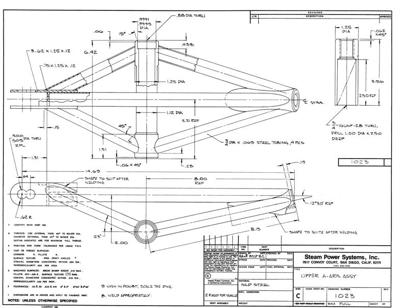

Detail design continues (upper control arm shown):

A-Arms:

Steering:

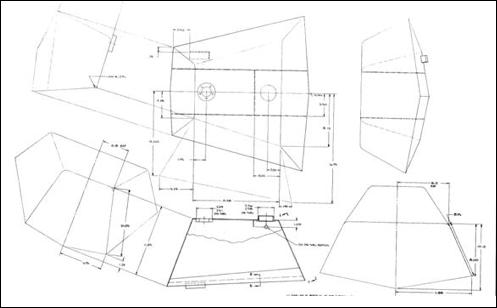

Body

Sections:

Fuel Tank:

…and a seemingly endless series of decisions, compromises, calculations, design challenges and solutions. Eventually, the last of the designs done, the parts made, the wiring complete, battery charged, the tank fueled, and…

ROLLOUT, DAY ONE!

24 July, 1984

Driven daily from San Diego to Temecula,

from ’84 – ’87, a total of 78,000 miles

When it’s cool, I get cold. When it’s damp, I get wet.

When I’m in, I’m HAPPY!

1987: The Yamahammer motor finally goes BLAM! (after 78,000 miles in the Shrike!) at the top of second gear on a freeway onramp, my marriage goes sour, I change jobs, and the Shrike follows along from garage to garage awaiting a new motor.

1994: I happen on a nice salvaged BMW K100 RT, I purchase it for the transplant, and end up restoring and selling the bike. The Shrike languishes in storage…

2000: Ready for another shot at the Shrike (which is now in need of a full restoration), the K1200 RS pops up. The crashed bike comes home, is stripped, and plans begin for the swap:

The first major decision was whether to keep the bike’s beautiful cast aluminum frame or build a tubular subframe to carry the engine and suspension loads. Easy decision: KISS: Keep It Simple, Stupid. Keep the bike frame and take advantage of the dozen or so perfectly located bolting points in both sides of the Bimmer frame right at the area of maximum stress, the swing-arm pivot:

After much careful measuring, several trial

templates, I had two steel plates with holes perfectly matched to the mating

holes in the Bimmer frame.

A rather complex bracket was hogged from billet aluminum to carry loads from the steering head into the chassis:

Meanwhile, back at the Ranch…

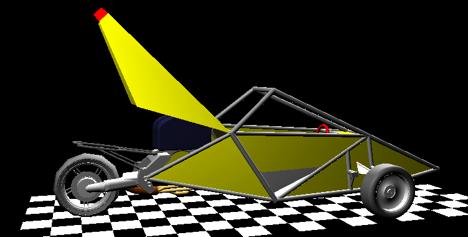

Work continued on both the scale model, and the layout. Having long since made the leap from ink on vellum to phosphor dots on a CRT, I began the time-intensive task of a 2D layout using AutoCAD:

I did a bit of simple 3D work on AutoCAD as well:

Perhaps one of the most pure examples of my preference for simplicity can be seen in the body design. It is derived directly from the shape of the chassis. Straight tubes, flat surfaces, no compound curves. The only curves in the body at all are the upper corners of the rear cover. The front surfaces of the body designed themselves: simply cover the flat surfaces. This was given an added kick by recessing the panels flush with the chassis tubes, letting the tubes show through the body. A bit like an exoskeleton. After hours of visualizing, sketching and paper modeling possible shapes for the rear, the simplest approach again won out: flat covers, as close to the hardware as possible.

Considerable effort was put into the model, partly as an aid in visualizing the final vehicle, and partly because I’ve always enjoyed modeling:

September, 2001:

The chassis and engine are mated, and work begins on the time-consuming “fiddly bits”: modifications to wiring, controls, instrumentation, lighting… At this point I encounter a speed-bump in the road to completion: a seizure; not of the engine but of the driver. It takes nearly two years to readjust to my medication and resulting changes in capabilities and energy level.

June 2003:

The bodywork, comprising composite aluminum/polypropylene panels called Alucobond (also Dibond), which are fitted flush to the chassis tubes.

First autocross, Jack Murphy Stadium, San Diego

Performance was a bit disappointing, as acceleration out of turns is limited by rear tire traction. Expected oversteer at high lateral G was not a problem, so long as power was closely controlled. I was told I was lifting an inside wheel on entry to one of the tighter turns, but I couldn’t feel it.

November 2004: Disassembly for paint, reassembly:

April 2007: Upholstered rear seat area, added dual four-point restraints:

Off to Sunday Breakfast in Fallbrook with the love of my life, Ellie

January 2008: Off to a well-earned retirement on our Angora goat ranch in Rogue River, Oregon.

The Shrike and I made the 950 mile trip straight through in about 20 hours, with a best mileage of 50 mpg on one tank.

Shrike and I have entered several car and bike shows here in the Medford / Grants Pass area, and earned one third place trophy, behind two Harleys in a Harley show!

With over 125,000 miles now, Shrike is beginning to look a bit tired around the edges. The deer strike didn’t help either, but it was the first demonstration of one aspect of the wedge-shaped chassis: deflecting struck vehicles or objects over or to the side. There was no entry into the driver’s compartment. The Shrike and I survived, the deer did not.

The Future: Emphasis here at BillyGoat Mountain Ranch (the name of our Colored Angora Goat operation) is on getting the infrastructure up to speed for the animals, and it will be a while before Shrike even gets a garage. In the mean time, Shrike and I are thoroughly enjoying retirement and the beautiful environs of Southern Oregon.

Planned future work for the Shrike includes redesigning the front suspension (most likely using early Miata bits), adding an anti-sway bar, changing the steering wheel bearing support structure to allow room for full view of the BMW instrument cluster, adding front fenders (there are some clever options in the Oregon Vehicle Code), and ultimately, a set of real plans, drawings, and construction manual for the Shrike. Nearer term, I’d like to do a low-budget video introduction to the Shrike, including an up-close walk-around, footage from the driver’s perspective, external shots of the Shrike on the road, and some technical shots of suspension motion and driver inputs. All in due time.

Later, then!

Dave Norton

nortonshrike.com ddnorton1@msn.com Dave Norton ©2016